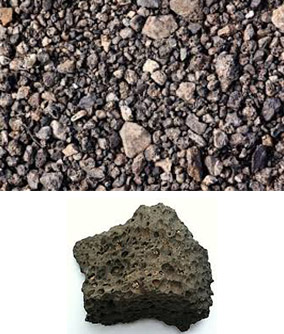

Cinder is a product which is used in filling the gaps in construction of buildings, dams, temples, bridges and others due to its quality of light weight and absorption of water and its form of sizes, and customization of the product.

Advantages:

Quality Information:

Type 1 : Full light weight blocks made from cinder ,easily laying and no need of crushing

Type 2 : Breaks easily, in case of water leakage it will absorb 70% of water, covers 90% area

Type 3 : Covers more area due to its size, ash type, absorbs 30 % water in case of leakage

Type 4 : It is a small pebble size, covering area 80%, absorbs water 50%

Type 5 : Has a radius of 2”, contains less ash comparatively, covers 60% area, absorbs 30 % water

Type 6 : Available in many shapes and sizes, it does not absorb water and is hard to break.

Type 7 : Same as type 2 but mixed with 30% pebble size cinder.

| Type One | 100 to 110 broken cinder blocks per ton covering area |

| Type Two | Height 12inc/1ft* length 12inc/1ft * width 12inc/1ft =1 cft 70 to 80 per ton covering area |

| Type Three | 50 to 60 per ton covering area |

| Type Four | 45 to 60 per ton covering area |

| Type Five | 35 to 50 per ton covering area |

| Type Six | 50 to 65 per ton covering area |